Nutrient Recovery Process

The anaerobic digestion process does not remove any of the nutrients (N P and K). It simply alters the form of the nutrients from particulate to soluble and gaseous products. A majority of the nitrogen is discharged from the digester as ammonium. A majority of the phosphorus discharge from the digester is associated with a fine particulate matter. Coarse liquid / solids separation (screw press, slope screen) does not capture a majority of the phosphorus or nitrogen.

In order to avoid fugitive ammonia nitrogen emissions and the adverse health and environmental consequences of those emissions E3 developed the nutrient recovery process that takes advantage of the high carbon dioxide concentrations in the liquid effluent from anaerobic digester.

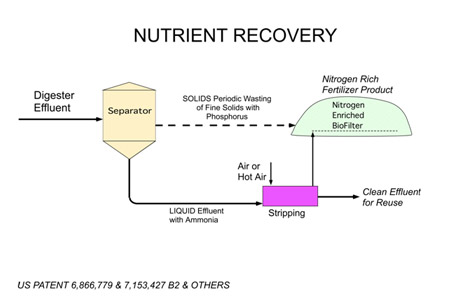

The digester effluent is first separated into a solid stream containing the course undigested fibers as well as the fine colloidal solids containing a majority of the phosphorus.

The liquid from the separator is then subjected to CO2 removal to increase the pH of the liquid. Air or hot air from an engine generator is utilized to strip ammonia nitrogen from the

effluent liquid. The ammonia nitrogen and air are then used to compost the anaerobic digester solids and thereby produce a nitrogen enriched compost / soil conditioner.

The process is an economical process for controlling ammonia and gaseous emissions from anaerobic digestion while producing a balanced (N P and K) nutrient enriched product.