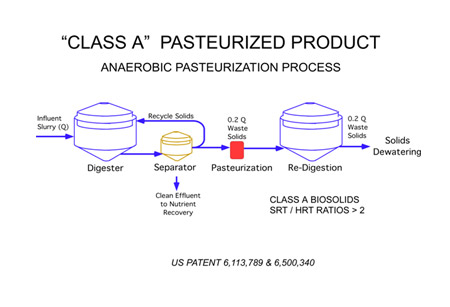

Pasteurization Process

In many cases it is desirable to produce a pathogen free soil conditioner or fertilizer that can be sold to the public or utilized on food crops. E3's pasteurization process is the most economical solution to producing a "Class A" pasteurized product. Energy requirements and pasteurization reactor size are significantly reduced since less than 20% of the influent waste is processed through the pasteurization unit. It is the most economical method of producing a "Class A" product.

In an existing digester system the influent digester can be converted to a high rate digester with a significantly greater capacity by simply adding a separator that recycles biomass

to the influent digester. Every hour a portion of the thickened slurry is transferred to a small pasteurization vessel that is heated to pasteurization temperatures and retained for the

desired period of time. The pasteurized product containing lysed cells is then transferred to a pathogen free digester where the solids are re-digested over a prolonged period of time.

An additional six to 15% conversion of solids to gas takes place in the re-digeston reactor. The overall process has achieved 80% volatile solids conversion to gas while producing a

Class A product in digesters smaller than conventional digesters.

The re-digested solids are then dewatered using conventional dewatering equipment that is operated for a fraction of the time of a conventional digestion system.